A paper making machine is a large industrial device that transforms raw materials into sheets of paper through a series of mechanical and chemical steps. These machines play a crucial role in the paper manufacturing process, enabling the mass production of items like packaging, hygiene products, and printed materials. The paper making machine supports daily life and industries by meeting global demand for essential goods. As seen in the paper cup machine market, high-capacity equipment can produce up to 5,000 cups per hour, with Asia-Pacific leading in modernization. The paper manufacturing process emphasizes sustainability, using renewable resources and advanced technology to reduce environmental impact.

Aspect | Impact on Daily Life and Industries |

Large-scale Production | Supports hygiene, packaging, and printing |

Sustainability | Promotes recycling and responsible sourcing |

Key Takeaways

A paper making machine turns raw materials like wood pulp and recycled fibers into sheets of paper through steps like forming, pressing, drying, and finishing.

The machine has two main parts: the wet end, which forms the paper sheet by removing water, and the dry end, which dries and strengthens the paper.

Quality control and automation help produce strong, smooth paper while reducing waste and energy use.

Sustainability is important in paper making, with mills using recycled fibers, eco-friendly materials, and water and energy-saving technologies.

Understanding the paper making process shows how advanced machines create everyday paper products efficiently and responsibly.

Paper Making Machine Structure

A modern paper making machine consists of two main sections: the wet end and the dry end. Each section plays a vital role in the paper manufacturing process, transforming raw pulp into finished paper with the desired properties.

Wet End

The wet end marks the beginning of the paper manufacturing process. Here, the machine receives a dilute fiber slurry from the head box, which spreads the mixture evenly onto a moving forming fabric. This fabric, also called the wire, supports the fibers as water drains away. Hydrofoils and vacuum boxes under the fabric help remove water quickly and evenly, while also moving fibers to create a uniform sheet. The forming section includes parts like the breast roll, suction boxes, and dandy roll, which smooth the surface and can add watermarks. Automation ensures that the sheet forms with consistent thickness and strength. Technologies such as wet end exhaust systems and retention agents improve water removal, sheet quality, and energy efficiency. The wet end sets the foundation for the rest of the paper manufacturing process by controlling fiber distribution and water content.

Note: Efficient water removal at the wet end not only boosts productivity but also supports sustainability by reducing energy use and improving drainage.

Dry End

The dry end continues the paper manufacturing process by removing most of the remaining water and finishing the sheet. The press section uses rollers and felts to squeeze water from the wet web, increasing its strength and density. After pressing, the paper passes through heated cylinders in the dryer section, which evaporate moisture and bond fibers together. The size press applies a starch solution to improve surface strength and printability. The paper then moves through the calendar, where iron rolls compress it for smoothness and uniform thickness. Finally, the pope reel and rewinder wind the finished paper into large rolls for shipment.

The dry end ensures the paper reaches the right dryness, strength, and appearance. Proper control at this stage prevents defects like brittleness or weak spots, which can affect the final product.

Parameter | Typical Range / Value |

Max. Machine Speed | 200–250 meters per minute |

Production Capacity | Approx. 10,000 reams per 8-hour shift |

Max. Paper Roll Diameter | Up to 1400 mm |

Max. Paper Roll Width | Around 1260 mm |

Overall Dimensions | 20m (L) x 3m (W) x 2.1m (H) |

A paper making machine combines these complex systems to deliver high-speed, high-quality output, making it essential to the paper manufacturing process.

How Paper is Made

The papermaking process transforms raw materials into finished rolls of paper through a series of carefully controlled steps. Each stage plays a vital role in shaping the properties and quality of the final product. Understanding how paper is made helps explain the complexity behind everyday items like books, packaging, and tissue.

Raw Material Preparation

Raw material preparation marks the beginning of the paper making process. Workers select and process fibers that will become paper pulp. The most common sources include:

Softwood fibers from pine, spruce, and fir trees, which provide long, strong fibers for durable paper.

Hardwood fibers from birch, eucalyptus, and maple, which offer shorter fibers for smoothness and printability.

Non-wood fibers such as bagasse (sugarcane waste), wheat straw, rice husk, bamboo, kenaf, hemp, jute, cotton, and flax. These alternatives support sustainability and specialty paper production.

Recycled fibers, which reduce environmental impact and support the pulp and paper process by blending with virgin fibers to maintain quality.

The quality of these raw materials directly affects the strength, texture, and appearance of the finished paper. High-quality, uncontaminated fibers produce consistent results, while impurities or excess moisture can cause defects and reduce yield. Modern mills use technologies like 'Moisture Gates' and strict inspection to monitor incoming materials. Certified forests and renewable sources help minimize ecological footprints.

Tip: Proper raw material preparation, including debarking and chipping for wood, ensures efficient pulping and high-quality paper.

Pulping

The pulping process breaks down raw materials into paper pulp, which serves as the foundation for sheet formation. Mills use several methods:

Mechanical pulping grinds wood fibers, retaining most lignin. This method yields more pulp but produces paper with lower strength and brightness, suitable for newsprint and magazines.

Chemical pulping dissolves lignin with chemicals, creating stronger and brighter pulp for writing, printing, and specialty papers. This method has lower yield and higher costs.

Biological pulping uses microorganisms to degrade lignin, balancing environmental impact and processing time.

Chemical and mechanical pulping methods each have unique environmental impacts. Chemical pulping releases effluents that can harm water bodies and aquatic life. Mechanical pulping uses less chemicals but produces more solid waste. Mills increasingly use recycled fibers and non-wood sources to reduce pollution and deforestation.

Forming the Sheet

The forming process begins when the paper making machine receives the watery paper pulp. The headbox distributes the pulp evenly onto a moving wire or forming fabric. The steps include:

The pulp slurry spreads across the wire, starting fiber formation.

Hydrofoils beneath the wire remove water and align fibers.

Suction boxes vacuum out more water, leaving a soft mat called the paper web.

After traveling 30-40 meters, the mat loses its wet sheen and forms the initial sheet.

This forming process determines the uniformity, thickness, and strength of the paper. Proper control ensures the fibers bond well and the sheet forms without defects.

Pressing

Pressing removes most of the remaining water from the paper web. The paper making machine uses press rolls and absorbent felts to squeeze the sheet, reducing moisture content from about 60-70% to 45-55%. Shoe presses and double-nip presses intensify dewatering, increasing sheet density and fiber bonding. This step prepares the sheet for efficient drying and improves its strength.

Press Type | Description | Efficiency Highlights |

Shoe Press | Improves dewatering and increases sheet dryness with fewer press nips. | Enhances wet web strength and runnability. |

Double-Nip Press | Combines shoe press with double-nip design for linear web run. | Removes bottlenecks and increases dryness before drying. |

Metal Belt Technology | Uses a hot metal belt to press and evaporate water simultaneously. | Increases dry content and production capacity. |

IntelliPress Linear | Compact section with shoe press for small/medium rebuilds. | Achieves high dryness and lowers energy consumption. |

Accurate moisture control during pressing is essential. Excess moisture can affect paper weight, dimensions, and folding ability. Advanced technologies help maintain uniform moisture and prevent defects.

Drying

The drying stage further reduces moisture to the desired level, typically 6-7%. The paper web travels around steam-heated cylinders, where heat evaporates water by conduction. Dryer hood air systems supply heated air for convection drying. Heat recovery systems reclaim energy from exhaust air, improving efficiency.

The paper passes over steam-heated dryer cylinders, gradually warming and evaporating moisture.

Heated air circulates in the dryer hood, removing evaporated water by convection.

Synthetic dryer fabrics and tension control maintain web contact for uniform drying.

Automation and sensors monitor steam and air parameters, optimizing moisture profiling.

Drying accounts for about 22% of total energy consumption in the pulp and paper process. Innovations like Superheated Steam Drying (SSD) can reduce energy use by up to 60%, supporting CO2 emission-free production.

Note: Effective drying ensures the paper reaches the correct dryness, preventing brittleness and improving quality.

Finishing and Winding

Finishing and winding complete the paper making process. Calendering passes the dried paper through heated rollers, improving smoothness, gloss, and thickness consistency. This step enhances printability, appearance, and packaging performance. Calendering parameters are adjusted to balance bulk, absorbency, and tactile properties.

Calendered paper runs smoothly on high-speed converting and packaging lines.

Proper finishing supports folding accuracy, stacking, and dimensional stability.

After finishing, the paper making machine winds the paper onto large steel spools. Workers split these spools into smaller rolls and rewind them onto cardboard cores for transport. Rolls receive moisture-resistant wrapping and labeling. For sheeted products, the rolls are cut into sheets, stacked into reams, and packaged for shipment. Additional coatings may be applied based on customer needs.

Tip: Careful finishing and winding protect the paper during transport and ensure it meets market requirements.

The papermaking process, from raw material preparation to winding, shows how paper is made in modern mills. Each step relies on advanced technology and strict quality control to produce high-quality paper for diverse uses.

Papermaking Process Quality

Quality Control

Quality control ensures that every sheet produced during the papermaking process meets strict standards for high-quality paper. Mills set clear quality standards and communicate them to all staff. They use a quality management system (QMS) to organize and monitor each step. Regular audits help identify areas for improvement. Operators track key parameters such as pulp consistency, refining intensity, retention aid dosage, sheet formation, caliper, moisture content, coating weight, and gloss.

Mills use statistical process control (SPC) to collect data and spot variations. Control charts like X-bar, R charts, and individual measurement charts help maintain process stability.

Advanced tools such as machine vision, spectroscopy, and chromatography provide detailed insights into product quality.

Continuous monitoring allows for quick corrective actions, keeping the process stable and ensuring high-quality paper at every stage.

Tip: Consistent quality control leads to fewer defects and less waste, supporting both customer satisfaction and sustainability.

Efficiency Features

Modern paper making machines include many features that boost efficiency and reduce waste. Automation handles repetitive tasks, lowering labor costs and improving consistency. IoT-enabled equipment tracks inventory and machine performance in real time. Predictive maintenance uses sensors and AI to spot problems before breakdowns occur, which reduces downtime.

Efficiency Feature | Description | Impact on Waste and Downtime Reduction |

Automated Impurity Removal | Sensors and AI detect and remove contaminants automatically. | Reduces contamination and downtime from manual sorting. |

Real-Time Monitoring | Sensors assess process conditions continuously. | Detects issues early and prevents breakdowns. |

Predictive Maintenance | Data analytics and AI predict equipment failures. | Minimizes stoppages and extends equipment life. |

Continuous Operation Design | Machines run without frequent stops. | Sustains productivity and reduces idle time. |

Energy Efficiency Mechanisms | Energy-saving technologies lower operational costs. | Supports sustainability and reduces environmental impact. |

Conveyor Systems Integration | Automated transport systems improve workflow. | Reduces contamination risk and bottlenecks. |

High Fiber Recovery Efficiency | Advanced designs maximize usable fiber extraction. | Increases raw material use and reduces waste. |

Automation and digital monitoring systems also improve safety by reducing human presence in hazardous areas. Real-time data allows operators to make quick decisions, keeping the papermaking process running smoothly. These features help mills produce high-quality paper efficiently, while supporting sustainability goals.

Sustainability in Paper Making

Eco-Friendly Materials

The paper making industry continues to shift toward eco-friendly materials to support sustainability. Manufacturers now use wood-based raw materials and wood-derived biochemicals, such as nanocellulose and lignin, as alternatives to fossil fuel-based substances. These innovations help reduce the environmental impacts of paper manufacturing. Composite materials that combine paper with barrier layers improve recyclability and performance. Research teams in Europe and North America invest in developing paper with better moisture and oxygen barriers, aiming for products that are both functional and easy to recycle.

Sustainable practices also include the use of biodegradable inks, like soy-based inks, and the adoption of recycled paper. The industry plants more trees than it harvests, supporting ecological balance. Compared to traditional materials, eco-friendly options may have higher initial costs but offer better durability, moisture resistance, and consumer appeal. Molded pulp packaging, made from recycled fibers and agricultural waste, costs less than plastic and supports a circular economy.

Factor | Traditional Materials | Eco-Friendly Materials |

Initial Cost | Lower | Higher |

Environmental Impact | Higher | Lower |

Consumer Appeal | Moderate | Higher |

Regulatory Compliance | Difficult | Aligned |

Water and Energy Use

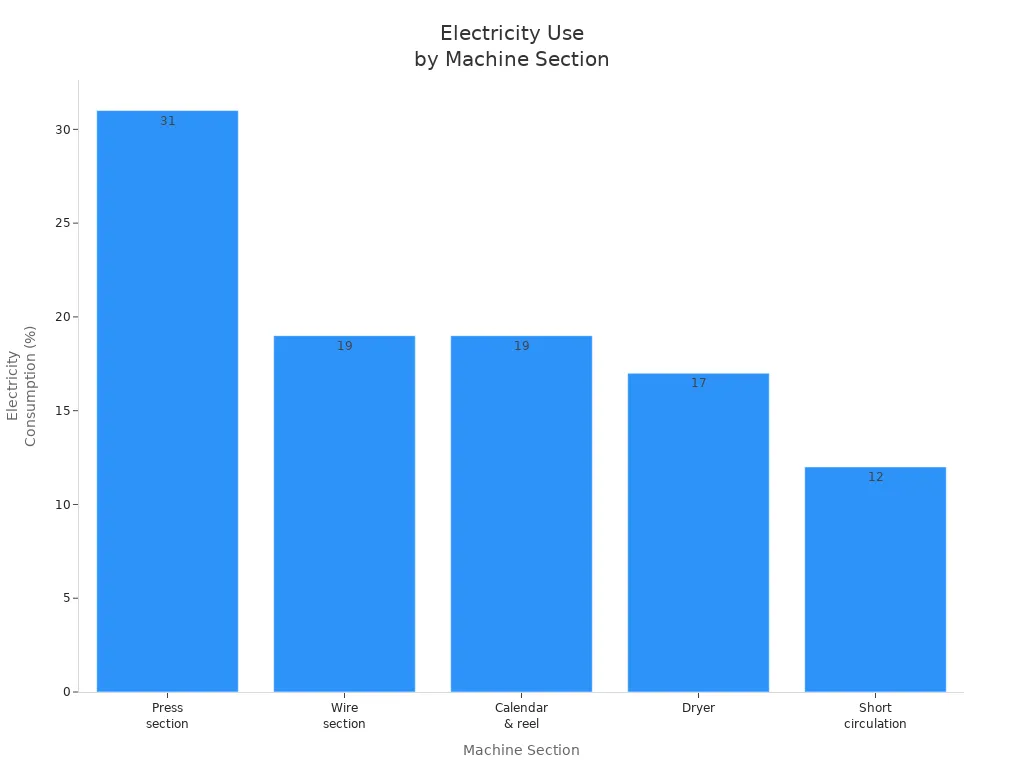

Paper making machines require significant amounts of water and energy. On average, a single machine uses about 140 MWh of energy, with newsprint machines consuming even more. Most of this energy powers pumps, drives, and water removal systems. Friction losses account for a large share of energy use, especially in the press and wire sections.

Modern mills use advanced water treatment and recycling systems to reduce fresh water use. Ultrafiltration creates ultrapure water for reuse, while closed mechanical seals and upgraded suction rolls minimize water loss. Automation and control systems help optimize energy use, making the process more efficient and supporting sustainability goals.

Tip: Upgrading equipment and using recycled fibers can lower both water and energy consumption, helping mills meet environmental targets.

Recycling

Recycling plays a central role in the sustainability of the paper industry. About 55 percent of global paper production uses recycled fibers, with some regions reaching rates as high as 75 percent. Recycling reduces landfill waste, conserves resources, and lowers energy use. Mills can recycle paper several times, though fiber quality may decrease with each cycle.

Benefits of recycling include:

Challenges remain, such as contamination of waste, fiber degradation, and the need for investment in recycling technology. Despite these issues, the industry continues to improve recycling rates and efficiency. Investments in new infrastructure and technology help overcome obstacles and support long-term sustainability.

A paper making machine transforms raw materials into finished paper through a series of precise steps. The process includes preparing fibers, forming sheets, pressing, drying, and finishing. Each stage uses advanced technology to ensure quality and efficiency. Mills focus on sustainability by using recycled fibers and eco-friendly methods. Understanding this process helps readers appreciate the innovation behind everyday paper products.

FAQ

What is a paper making machine?

A paper making machine creates paper from raw materials like wood pulp or recycled fibers. The machine uses mechanical and chemical steps to form, press, dry, and finish sheets of paper for many uses.

How does a paper bag making machine differ from a paper making machine?

A paper bag making machine shapes and seals paper into bags. The paper making machine produces the raw paper rolls first. Factories use both machines to create packaging products.

Can a paper cup making machine use recycled paper?

A paper cup making machine can use recycled paper if the material meets hygiene and strength standards. Mills often blend recycled fibers with virgin pulp to ensure safe and sturdy cups.

What maintenance does a paper making machine require?

Operators clean and inspect the paper making machine daily. They check rollers, replace worn parts, and monitor sensors. Regular maintenance prevents breakdowns and keeps production efficient.

Why do factories choose automated paper making machines?

Factories select automated paper making machines for higher speed, better quality, and lower labor costs. Automation helps monitor the process, reduce waste, and improve safety for workers.