A paper making machine transforms wood chips and recycled materials into smooth, high-quality sheets through a carefully controlled paper manufacturing process. Modern machines use advanced controls to monitor each step, increasing efficiency and ensuring consistent results.

Sustainability remains a key focus, with mills recycling water and reducing energy use.

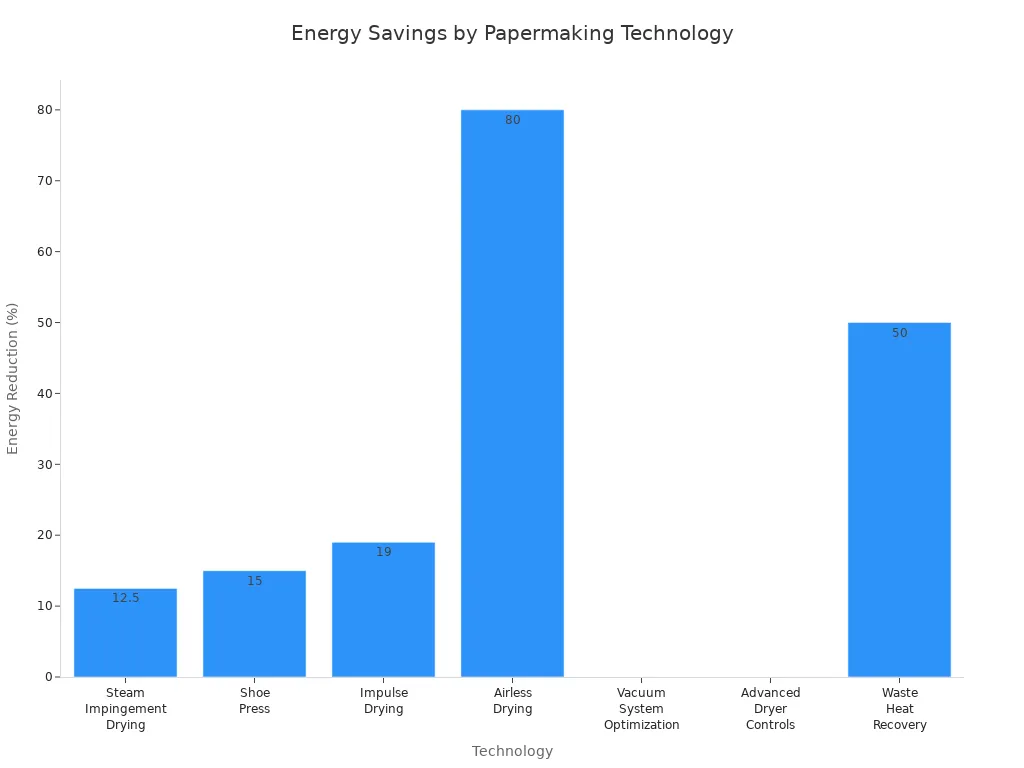

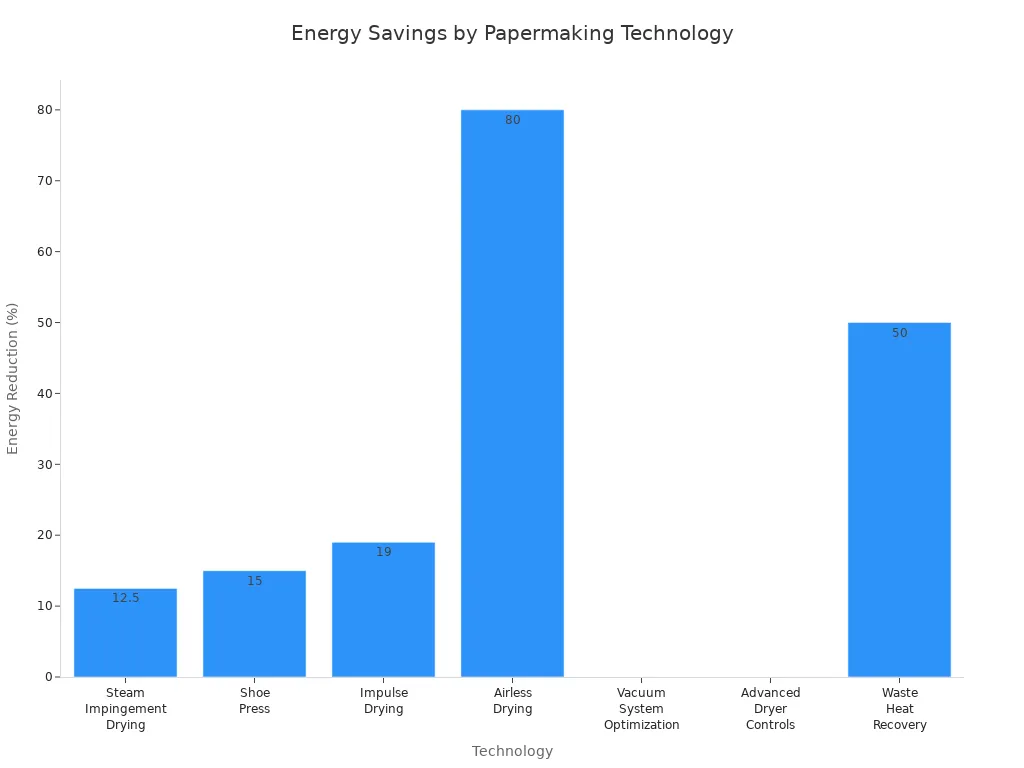

Technology or Measure | Efficiency and Quality Improvements |

Steam Impingement Drying | Saves 10-15% energy, improves drying efficiency. |

Shoe (Extended Nip) Press | Reduces energy use, improves paper strength and quality. |

Impulse Drying | Saves 18-20% energy, increases drying rates and paper dryness. |

Airless Drying | Achieves 70-90% thermal energy reduction, enhances drying efficiency. |

Vacuum System Optimization | Saves significant power, improves dewatering efficiency. |

Advanced Dryer Controls | Improves process control, enhances paper uniformity. |

Waste Heat Recovery from Drying | Reduces energy use by up to 50%, lowers costs and environmental impact. |

The papermaking process uses these innovations to deliver strong, uniform paper while supporting sustainability. The paper manufacturing process relies on quality checks, resource management, and technology to answer the question: how is paper made from start to finish?

Key Takeaways

Paper making machines turn wood chips and recycled materials into smooth, strong sheets through precise steps and advanced controls.

Raw materials like wood pulp, recycled fibers, and non-wood sources are prepared carefully to ensure quality and sustainability.

The forming section shapes the pulp into uniform sheets using machines like Fourdrinier and cylinder types, each suited for different paper grades.

Pressing and drying remove water efficiently, improving paper strength and saving energy with modern technologies.

Sustainability is key, with mills using eco-friendly chemicals, recycling water, saving energy, and managing forests responsibly.

Raw Material Preparation

The pulp and paper process begins with careful raw material preparation. Mills use a variety of sources to create paper pulp. The most common raw materials include:

Wood pulp, which dominates the global supply and ensures consistent quality.

Recycled paper, which has become more important as mills focus on sustainability and improved recycling technology.

Non-wood fibers, such as bamboo, hemp, and agricultural residues, which offer unique qualities and a lower environmental impact.

Recycled fibers, which help reduce waste and support eco-friendly production.

Debarking and Chipping

The first step in raw material preparation involves turning logs into small, uniform chips. Mills follow a precise sequence:

Workers feed logs into a debarking drum. The drum tumbles the logs and sprays them with water jets to remove the bark. This step prevents contamination and protects machinery.

Clean logs move to a high-speed chipper. The chipper uses sharp, rotating blades to cut the logs into small, even wood chips.

Uniform chip size is essential. It ensures efficient cooking and consistent fiber separation during the pulping process, which affects the final quality of the paper pulp.

Pulping Methods

After chipping, mills use different pulping methods to separate fibers. The two main types are mechanical and chemical pulping. The table below compares their key features:

Aspect | Mechanical Pulping | Chemical Pulping |

Yield | High (90-95%) | Low (40-55%) |

Paper Strength | Lower strength | Higher strength |

Brightness | Lower brightness | Higher brightness |

Lifespan | Limited lifespan (yellowing) | Greater longevity |

Mechanical pulping keeps most of the wood mass, resulting in high yield but lower quality. Chemical pulping removes lignin and impurities, producing stronger, brighter, and longer-lasting fibers. Chemical pulping accounts for over 70% of global pulp production, with mechanical pulping used mainly for products like newsprint. Mills choose the pulping process based on the desired paper quality and end use.

Pulp Processing

Washing and Bleaching

Washing and bleaching play a crucial role in the pulp and paper process. Mills remove contaminants from paper pulp to improve brightness and quality. The main contaminants include adsorbable organic halides (AOX), dioxins, furans, resin acids, chlorinated lignins, phenolic compounds, and synthetic organic compounds. These substances often result from chemical reactions during pulping and bleaching. Workers use washing steps to eliminate these harmful materials, which reduces environmental discharge and enhances pulp quality. Advanced bleaching techniques, such as elemental chlorine-free (ECF) and totally chlorine-free (TCF) bleaching, further reduce harmful residues.

Common bleaching agents include chlorine, chlorine dioxide, hydrogen peroxide, and sodium hydroxide. Chlorine reacts with lignin to solubilize it, while chlorine dioxide serves as a powerful oxidizing agent in ECF bleaching. Hydrogen peroxide brightens the pulp, and sodium hydroxide helps in both cooking and bleaching. Mills also use less common agents like peroxyacetic acid, potassium peroxymonosulfate, and enzymes such as xylanase. Environmental concerns have led to reduced use of elemental chlorine, as it can form dioxins.

Tip: Mills that use chlorine-free bleaching and eco-friendly chemicals help protect the environment and produce cleaner, high-quality paper.

Refining and Beating

Refining and beating change the structure of paper pulp fibers. Operators use mechanical treatment to induce internal fibrillation, which increases fiber swelling and flexibility. This process improves fiber bonding and sheet densification. External fibrillation, fines formation, fiber shortening, and fiber straightening also occur during refining. The increased availability of hemicellulose on fiber surfaces enhances fiber-to-fiber bonding. These changes result in denser sheets with higher tensile strength and stiffness. Refining also affects the electrokinetic properties and surface charges of fibers, which influence paper quality. The overall effect is stronger, stiffer, and more uniform paper.

Sizing and Coloring

Sizing and coloring agents give paper its final properties. Mills use both natural and synthetic sizing agents, such as rosin, alkyl ketene dimer (AKD), alkenyl succinic anhydride (ASA), starch, and styrene acrylic. Sizing agents fall into two categories: internal (added to the pulp) and surface (applied after sheet formation). These agents increase water resistance by creating hydrophobic barriers, reduce paper porosity, and prevent water penetration. Sizing also improves printability by enhancing ink absorption and reducing ink bleeding. Mechanical properties like tensile strength, tear resistance, and foldability improve with proper sizing.

Coloring agents, including pigments and dyes, provide the desired shade and brightness. The choice of sizing and coloring agents depends on the intended use of the paper. For example, AKD suits packaging, rosin works for specialty papers, and starch is common in printing papers. Mills select agents to ensure the paper meets specific requirements for strength, appearance, and performance.

Sheet Formation in Paper Making Machine

The sheet formation stage is the heart of the paper making machine. This stage transforms the processed pulp into continuous sheets, setting the foundation for the final paper's strength, smoothness, and uniformity. The forming process relies on precise control and advanced engineering to ensure high-quality results.

Wet End and Headbox

The wet end of a paper making machine prepares the pulp slurry for sheet formation. The headbox plays a critical role in this process. It converts the pulp flow from the pipeline into a thin, even jet that spreads across the entire width of the forming fabric. This step is essential for producing uniform sheets.

The pulp slurry first enters a pulsation dampening tank, which reduces pressure fluctuations and ensures a stable flow.

The slurry moves to the high-consistency (HC) header, distributing it evenly across the headbox width.

The low-consistency (LC) header controls the pulp's consistency.

Operators use a dilution control valve to adjust water addition, precisely controlling fiber concentration.

The mixing chamber thoroughly blends the diluted pulp for uniform consistency.

The distribution tube spreads the slurry evenly across the headbox width.

The stilling chamber calms the flow, reducing turbulence.

A turbulence generator reintroduces controlled turbulence to keep fibers suspended and prevent clumping.

The pulp exits through a nozzle, directing the slurry evenly onto the wire.

Adjustable lips at the nozzle control the slurry's thickness and velocity, fine-tuning distribution.

The slurry is finally deposited onto the moving wire section, where uniform fiber distribution is critical for paper quality.

The headbox ensures that the pulp slurry matches the speed of the forming fabric. This careful control prevents fiber clumping and maintains even thickness across the sheet. Operators can adjust the slice lips and dilution valves to fine-tune the basis weight and fiber distribution, which directly impacts the uniformity and strength of the finished sheets.

Note: Uniform sheet formation at the wet end is essential for producing high-quality paper with consistent properties.

Forming Section and Water Removal

In the forming section, the diluted pulp slurry is poured onto a moving forming fabric, also known as the wire. The forming fabric acts as a permeable support, allowing water to drain while retaining the fibers. This step marks the beginning of the forming process, where the pulp transforms into a continuous web.

The forming fabric's mesh structure influences how fibers settle and align. Gravity and suction boxes beneath the wire help remove water quickly. As the web moves forward, vacuum-assisted drainage further reduces water content. The forming process at this stage ensures that fibers distribute evenly, preventing clumps and weak spots in the sheets.

Operators use several methods to remove water from the pulp during sheet formation:

The pulp suspension starts with a very low solid content, usually around 0.2% by weight.

The suspension is stirred to ensure homogeneity.

Vacuum filtration removes a significant portion of water, forming the sheet on the fabric.

Pre-drying under vacuum and heat further reduces moisture.

The sheet is then peeled off and dried again to reach the desired dryness.

After the forming section, the web still contains a high percentage of water, but it is much drier than the initial slurry. The forming process at this stage sets the foundation for the paper's structure and quality.

Fourdrinier and Cylinder Machines

Two main types of paper making machines dominate the industry: Fourdrinier and cylinder machines. Each type uses a different forming process and produces different grades of paper.

Aspect | Fourdrinier Machine | Cylinder Machine |

Paper Formation | Single uniform layer formed on a continuously moving flat wire mesh. | Multiple layers formed on rotating cylinders partially submerged in pulp vats, then pressed together. |

Paper Grades | Produces smoother, thinner papers ideal for printing, writing, and lightweight grades (40-120 gsm). | Produces thicker, multi-ply papers like cardboard, linerboard, and packaging materials (above 120 gsm). |

Operating Speed | Higher speeds, typically 1800-2000 meters per minute. | Slower speeds, typically 200-600 meters per minute. |

Fiber Orientation | Fibers aligned mainly in machine direction, resulting in anisotropic strength (2:1 to 3:1 ratio). | Fibers distributed more evenly across directions, providing balanced strength (around 1.5:1 ratio). |

Pulp Consistency | Slightly higher (0.8%-1.2%), aiding sheet formation and drainage. | Lower (0.5%-1%), facilitating smooth layering of multiple plies. |

Maintenance | More intensive due to complexity and numerous moving parts. | Simpler mechanical structure, requiring less frequent maintenance. |

Output Characteristics | Produces uniform, smooth, thin sheets suitable for fine papers and printing. | Produces thicker, stronger multi-ply sheets suitable for packaging and specialty papers. |

The Fourdrinier machine dominates the modern paper making machine market, accounting for more than 60% of installations worldwide. This machine excels at producing smooth, thin sheets for printing and writing. Cylinder machines, while less common, are preferred for thicker, multi-ply papers such as cardboard and packaging materials. Both types of papermaking machine rely on precise control of the forming process to achieve the desired paper properties.

Tip: The choice between Fourdrinier and cylinder machines depends on the required paper grade and end use. Fourdrinier machines offer speed and uniformity, while cylinder machines provide strength and thickness for specialty applications.

Pressing, Drying, and Finishing

Press Section

The press section of a paper making machine removes water from the wet paper web by applying mechanical pressure. Press rolls squeeze the web, and absorbent press felts help draw out water through capillary action. Advanced presses, such as shoe presses, increase the time and pressure applied, which improves water removal and protects the paper sheet. After the forming section, the paper web contains about 60-70% water. The press section reduces this moisture to around 45-55%. This step lowers the energy needed for drying and improves both paper quality and production efficiency.

Common types of presses include:

Sponge presses, which use a clean sponge for individual sheets.

Simple plywood presses, tightened with C-clamps.

Hydraulic presses, using jacks for thicker or multiple sheets.

Vacuum table presses, which draw water out using suction.

Adapted presses from other industries, such as book or flower presses.

Portable classroom presses and homemade presses for specific needs.

Drying Section

The drying section removes most of the remaining moisture from the paper web. Steam-heated cylinders dry the web to the desired moisture content, which is important for strength and stability. Energy efficiency in this stage comes from several strategies:

Heat recovery systems capture waste heat to pre-heat incoming air.

Dryer hood designs improve heat recirculation.

Proper maintenance of air filters and ducts ensures efficient airflow.

Advanced control systems use sensors to maintain optimal humidity.

Innovations in dryer fabrics and steam management reduce energy use.

Modern drying technologies include microwave drying and advanced tissue drying systems, which further improve efficiency and product quality.

Surface Sizing and Calendering

Surface sizing and calendering are key finishing steps. Surface sizing prepares the paper surface, improving brightness, smoothness, and printability. Calendering compresses the paper surface, reducing roughness and increasing gloss. This process changes the fiber structure, making the surface more uniform and better for printing. Calendering equipment includes machine finish, supercalendered finish, and plater finish types, each offering different levels of smoothness and gloss.

Winding and Cutting

After finishing, the paper is wound into large jumbo rolls. Slitter rewinders cut these rolls into narrower strips using blades, then rewind them onto new cores. The process uses precise tension control and web alignment systems to prevent damage and ensure consistency. Automated systems can adjust roll width, density, and detect defects. The final product can be further cut into sheets or smaller rolls, ready for packaging and shipping.

Quality Control and Sustainability in Papermaking Process

Real-Time Quality Checks

Modern mills use advanced systems to monitor the papermaking process and maintain high-quality paper standards. A Quality Control System (QCS) measures properties like moisture content, smoothness, roughness, and two-sidedness in real time. These digital tools collect and analyze data instantly, allowing technicians to adjust settings and prevent defects. Machine learning and artificial intelligence now help predict issues before they happen, but skilled workers still oversee the process. Mills combine these digital systems with regular equipment inspections to ensure the paper manufacturing process stays reliable and efficient. This approach reduces downtime and keeps product quality consistent.

Quality Parameter Category | Examples of Parameters Measured |

Physical Properties | Basis weight, thickness, color |

Chemical Properties | Moisture content, ash content |

Surface Properties | Smoothness, roughness, gloss, whiteness |

Structural Properties | Two-sidedness |

Note: Surface properties like roughness and gloss affect how well paper prints and looks. Moisture content is also critical for strength and stability.

Environmental Practices

Sustainability guides every step of the paper manufacturing process. Mills have replaced chlorine-based bleaching with safer methods to avoid harmful chemicals. They use recycled fibers and alternative sources like bamboo or agricultural waste to protect forests and reduce energy use. Water recycling systems and advanced treatment technologies help mills use less water and keep it clean. Many facilities now rely on bioenergy from renewable fuels, lowering their carbon footprint. Automation and digital controls reduce waste and save energy. Responsible sourcing and forest management support biodiversity and reforestation. Supply chain improvements, such as sourcing materials closer to the mill, further reduce the environmental impacts of paper manufacturing.

Eliminate chlorine-based bleaching

Use recycled fibers and alternative raw materials

Recycle and treat water efficiently

Improve energy efficiency with modern equipment

Use renewable bioenergy

Practice responsible forest management

Optimize supply chains for lower emissions

Tip: Choosing high-quality paper made with sustainable practices helps protect the environment.

Packaging and Shipping

Mills protect finished paper products with careful packaging and shipping methods. They use materials like bubble wrap, foam, and sturdy boxes to prevent damage from rough handling or movement during transport. Custom packaging solutions fit each product’s size and weight, reducing empty space and risk of harm. Moisture-resistant materials and tamper-evident seals add extra protection. Mills test packaging by simulating drops and impacts, then improve designs based on feedback and performance data. Efficient logistics, such as using rail instead of trucks or planning delivery routes with AI, help lower emissions and support sustainability. These steps ensure that high-quality paper arrives safely and with minimal environmental impact.

The papermaking process transforms raw materials into finished paper through a series of steps: preparation, pulping, washing, bleaching, sheet formation, pressing, drying, and finishing. Machinery such as Fourdrinier and cylinder machines ensures efficiency and consistent quality. Quality control systems monitor every stage, while sustainability practices reduce waste and energy use. The paper manufacturing process relies on advanced technology and environmental management. In summary, how paper is made involves precise control, modern equipment, and a strong commitment to quality and sustainability.

FAQ

What is a paper making machine?

A paper making machine turns pulp into continuous sheets of paper. It uses advanced controls to manage each step, from forming the sheet to drying and finishing. This machine ensures high-quality, uniform paper for many uses.

How does a paper making machine differ from a paper bag making machine?

A paper making machine creates large rolls or sheets of paper. A paper bag making machine uses these sheets to cut, fold, and glue paper into bags. Each machine serves a unique role in the paper product industry.

Can a paper making machine produce paper for cups and bags?

Yes. A paper making machine can produce base paper for both paper cup making machines and paper bag making machines. The machine adjusts thickness, strength, and surface finish to meet the needs of each product.

What maintenance does a paper making machine require?

Operators must clean, inspect, and lubricate the paper making machine regularly. They check for worn parts and replace them as needed. Proper maintenance keeps the machine running smoothly and extends its lifespan.

Are paper making machines environmentally friendly?

Modern paper making machines use recycled fibers, save energy, and recycle water. Many mills use eco-friendly chemicals and renewable energy. These steps help reduce the environmental impact of paper production.